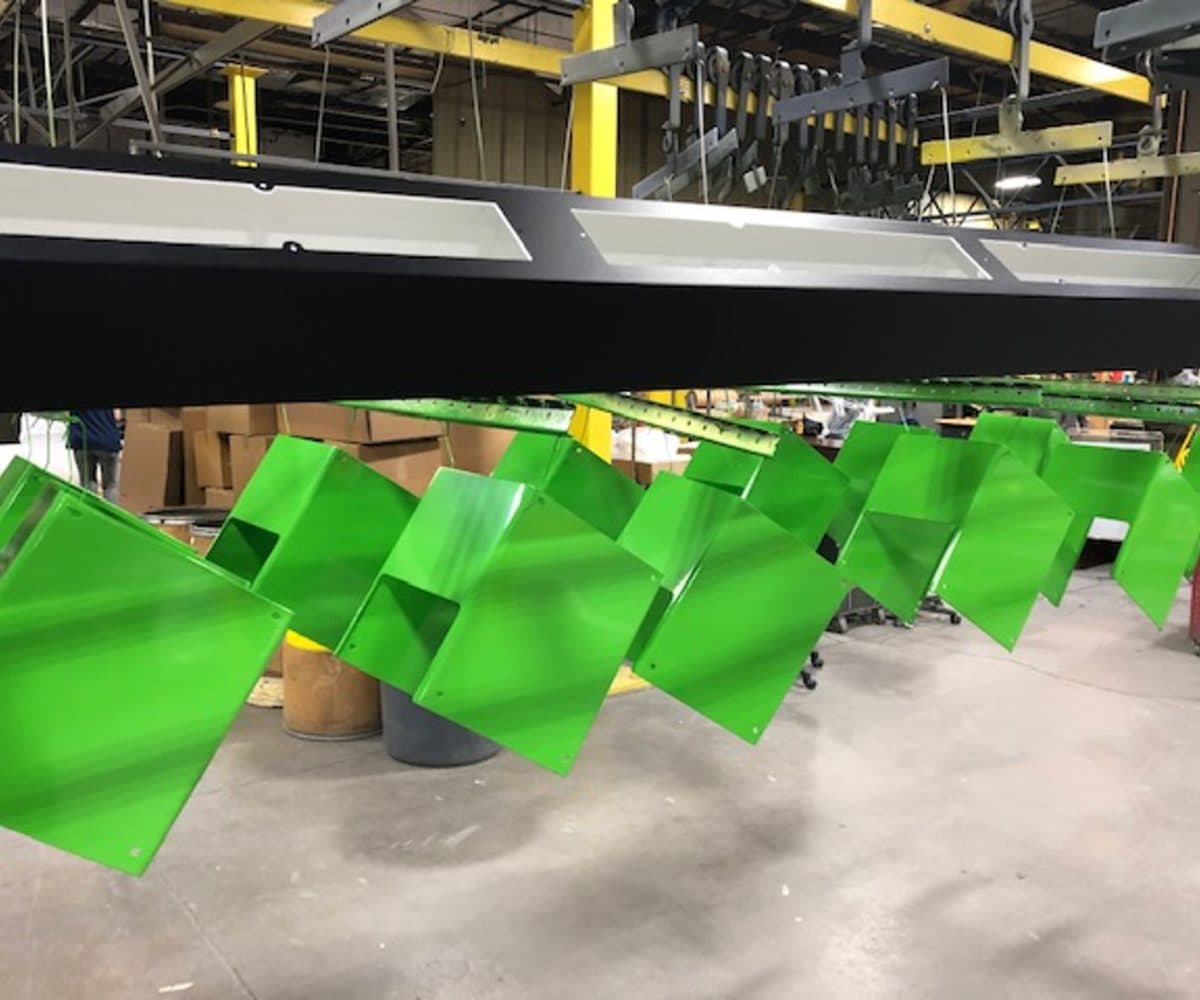

Powder Coating

An electrostatic process whereby charged powder particles are coated and heat-sealed onto surfaces, creating a beautiful protective finish. Industrialex is the only facility in Colorado with two full auto-lines dedicated to this service.

What is powder coating?

The powder coating process is a common form of coating that is applied as a dry powder and then cured under heat to form a hard finish. It’s commonly used for coating metals.

The process involves electrostatically charging the powder particles and then applying them to the surface of the object to be coated. This coating is then cured under heat, where it chemically reacts to form a tough, durable finish.

What makes our powder coating service unique?

Because of our longstanding history as a leader in the industry, we have built exceptional relationships with our trusted vendors. As a result, we have access to thousands of colors and are able to procure powder quickly.

We have four large powder ovens and two auto-wash / auto-dry lines, which means we can fulfill orders on products of any size.

Furthermore, we are experts in coating every type of product out there. No project is too big or too complex for Industrialex to handle.

Applications

Aluminum, Steel, Iron

Textures

Smooth, Matte, Fine Texture, Rough Texture, Hammer-Tone

Finishes

Matte, Semi-Gloss, Gloss, Hammer-Tone

Our Trusted Vendors

Our Powder Coating Process

Receipt of Product

Product is received, entered into our EMS/QMS system, and hung on our auto-line.

RoHS Chromate Conversion (Optional)

Certain aluminum and magnesium products will go through pre-treatment in our tanks.

Auto-Wash + Auto-Dry

All particulates are removed to ensure the surface is ready for coating application.

Powder Coating Applied

The coating of your choice / our recommendation is electrostatically applied to your product.

Heat Sealing of Coating

Product is heated to seal the coating.

Inspection, Packaging, Shipping

Your product is inspected for quality, packaged, and shipped back to you.