Liquid Coating

The spray application of paint onto products. We are the largest provider of this service in Colorado, with four liquid-paint booths. We offer polyurethane, water-based, solvent-based, high-solid paints, and specialty finishes.

What is liquid coating?

The Liquid Coating process is the spray application of paint onto products. We offer polyurethane, water-based, solvent-based, and high-solid paints, as well as specialty finishes such as conductive coatings and dry film lubricants. The finishes can be smooth or textured according to customer specifications. Custom-matched colors are available. Our Liquid Coating department can accommodate requirements from economical applications to “Class A” coatings. Before paint application, parts can be masked per customer specifications.

What makes our liquid coating service unique?

With four separate liquid booths, we are currently the largest liquid coating provider in Colorado. We also have extensive experience meeting military specifications (QPL) and can adapt to changes rapidly.

Applications

Plastics, Aluminum, Iron, Steel, Magnesium

Textures

Smooth, Fine, Matte, Rough

Finishes

Polyurethane, Water-Based, Solvent-Based, High Solid Paint, and Specialty Finishes

Our Trusted Vendors

Our Liquid Coating Process

Receipt of Product + Masking (Optional)

Product is received, entered into our EMS/QMS system, and masked (if needed).

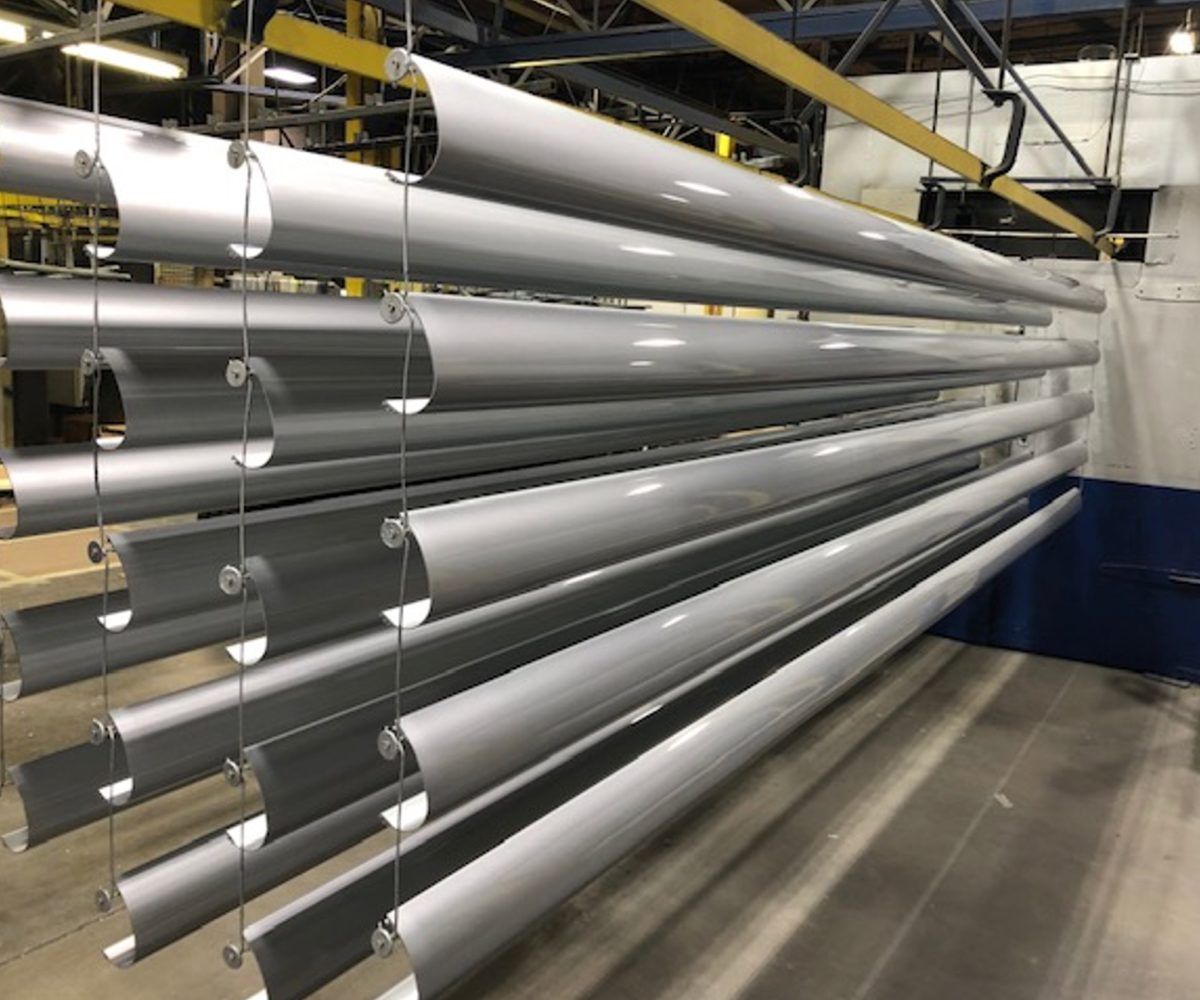

Hung in Liquid Booth

Product is hung in one of our four liquid booths.

Liquid Coating Application

Primer is added, and and the coating of choice is applied.

Drying and/or Baking

Product is dried, or if needed, baked at a low temperature, to seal the coating.

Inspection, Packaging, Shipping

Product is inspected for quality, packaged, and shipped back to you.