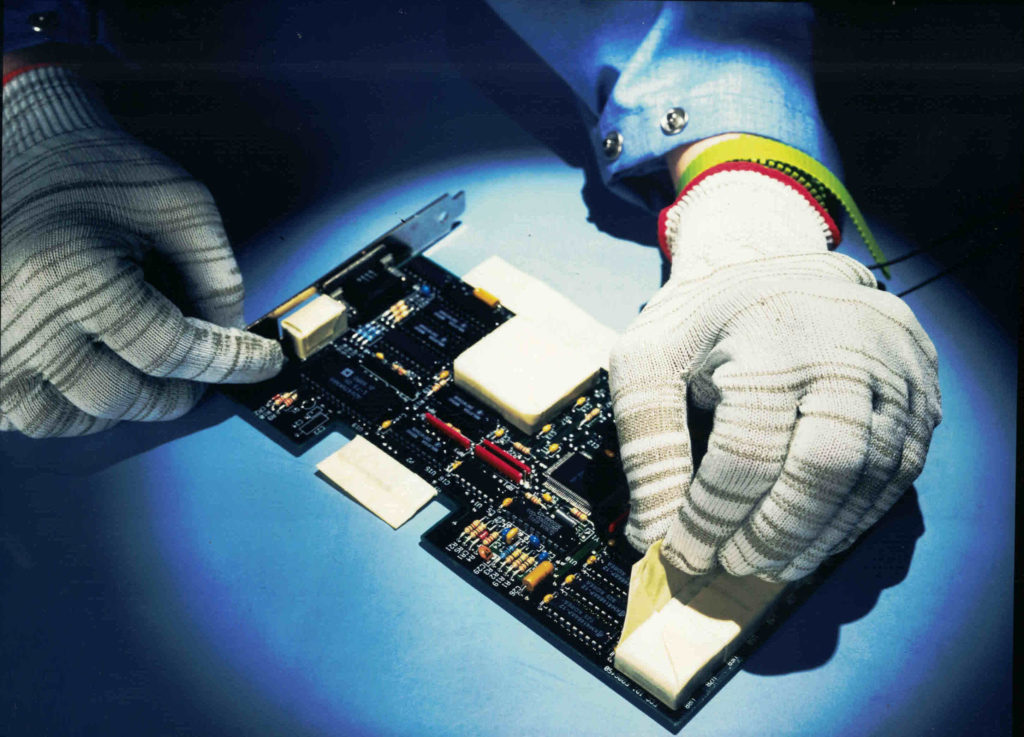

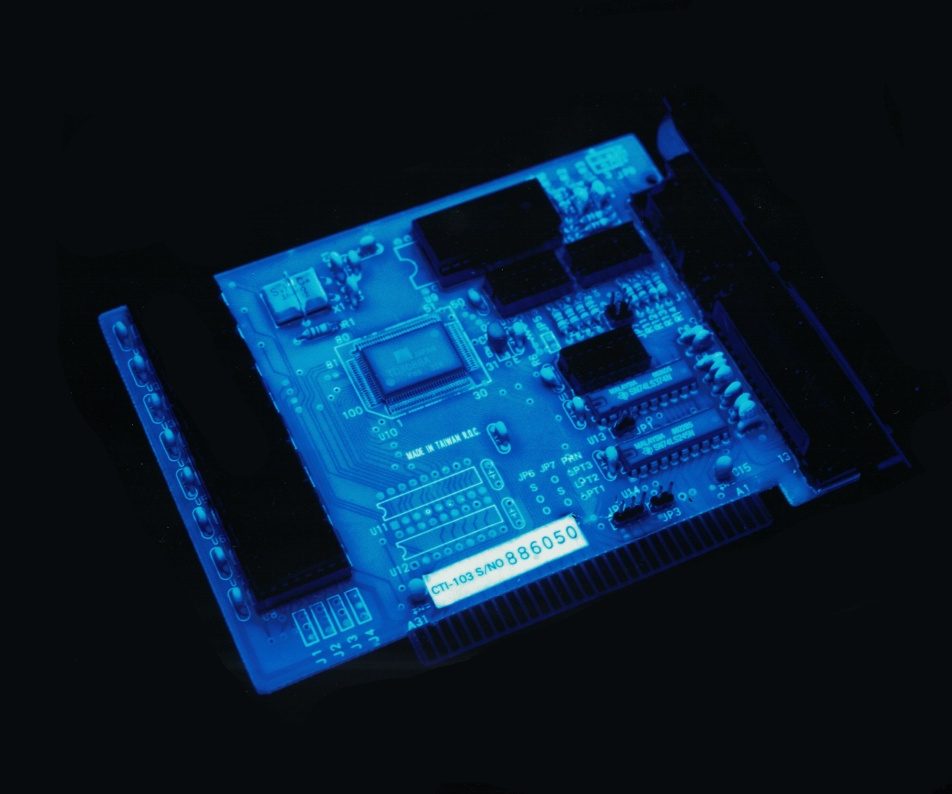

Conformal Coating

Within our EPA-approved Class A spray booth, silicon, urethane, and acrylic are applied to printed circuit boards and related electronics products to extend their longevity from a range of degrading factors. We also provide epoxy resin coating, via our military-grade injection gun, for boards needing extra protection.

Conformal Coatings are specially formulated materials made of silicon, urethane, and acrylic. These materials are designed to protect printed circuit boards (PCBs) and related equipment from environmental factors like rust, electric static, water, humidity, etc. This process improves and extends the circuit board’s working life and ensures security and reliability of performance. These coatings “conform” to the circuit board’s contours and its components, creating a thin (25-50 micron) layer that is both lightweight and flexible. Conformal Coatings protect circuitry from hazardous chemicals (e.g. fuels, coolants, etc.), vibration, moisture, salt-spray, humidity, and high temperature. In an uncoated circuit board, these conditions can cause corrosion, mold growth, and power leakage resulting in operational failure.

Conformal Coatings provide protection for electronic circuitry in a wide range of products including:

- Programmable highway signs.

- Mobile phones.

- Pacemakers.

- Washers and dryers.

- Microwave ovens.

- Security systems.

- Engine management systems.

- Navigation systems.

- Radar control systems.

As part of our Conformal Coating division, we also offer encapsulation services. This is a process which coats the product in a thick two-part epoxy coating, providing an even greater level of protection for the products in tougher environments.

Applications

PCBs, Electrical Circuits, Wirings

Finishes

Silicone, Urethane, Acrylic, Epoxy